Introduction

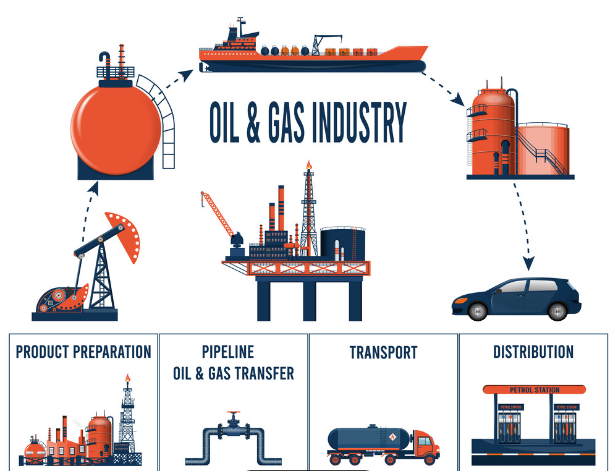

The oil and gas sector stands at the crossroads of technological advancements and increasingly complex challenges. Given the volatile nature of commodity prices, geo-political factors, and stringent regulatory requirements, companies operating in this sector must implement sound risk assessment and supply chain optimization strategies to maintain a competitive edge. In this post, we will explore how integrating risk assessment strategies with advanced supply chain optimization methods can unlock unprecedented efficiencies and add value to your operations.

The Need for Risk Assessment

The first step in optimizing supply chain operations in the oil and gas sector is understanding and assessing the risks involved. These risks can range from geopolitical instability affecting supply chains to environmental considerations like extreme weather conditions disrupting operations. Proper risk assessment gives companies the information they need to either mitigate these risks or be prepared with contingency plans to ensure uninterrupted operations.

Real-World Case Study 1: Geo-Political Risks

A global oil and gas company operating in various parts of the world was facing issues with supply chain disruptions due to political instability in some regions. By using sophisticated risk assessment models that considered various factors such as political climate, local laws, and even cultural issues, the company was able to predict potential disruptions and come up with alternative supply chain routes.

Supply Chain Optimization: Beyond Traditional Models

Traditionally, supply chain models in oil and gas have been focused on just-in-time delivery, minimal inventory costs, and lean management strategies. While these are still relevant, they are not sufficient for today’s complex landscape. Next-level optimization strategies are now incorporating Big Data analytics, Internet of Things (IoT) sensors, and Artificial Intelligence (AI) to provide real-time information, predictive analytics, and more efficient operation strategies.

Real-World Case Study 2: Leveraging Technology for Optimization

Another leading name in the industry applied AI algorithms to their supply chain logistics, achieving remarkable efficiencies. AI was used to predict equipment failures before they happened, allowing for preventive maintenance and avoiding expensive downtimes. Big Data analytics helped in scrutinizing delivery times, costs, and supplier performance, thereby streamlining operations and significantly reducing costs.

Integrating Risk Assessment and Supply Chain Optimization

The real value comes from integrating risk assessment strategies directly into supply chain optimization plans. This means creating risk profiles for different elements of the supply chain and using that data to inform optimization strategies. When these two elements are combined, it creates a powerful tool for not only predicting and mitigating risks but also for realizing efficiencies that would not be possible otherwise.

Real-World Case Study 3: Integrated Strategy

A medium-sized operator in North America successfully integrated its risk assessment strategies with its supply chain optimization. By doing so, they managed to reduce their operational downtime by 25% and achieve cost savings of 18% within the first year of implementation.

Conclusion

Navigating the complexities of the oil and gas sector requires a deep understanding of both risk assessment and supply chain optimization. Companies that have successfully integrated these two elements have been able to unlock significant value and efficiencies in their operations. As technologies continue to advance, the opportunities for further efficiencies are limitless.