Introduction

The Oil & Gas sector has been under scrutiny for years due to its safety record. With increasing regulatory oversight and a demand for safer operations, companies are now obliged to exceed baseline safety standards. Advanced technologies and methodologies have paved the way for enhanced safety protocols, which are now indispensable for any business in the sector. In this blog post, we will explore cutting-edge safety measures that go beyond merely meeting regulatory requirements.

The Evolution of Safety Measures

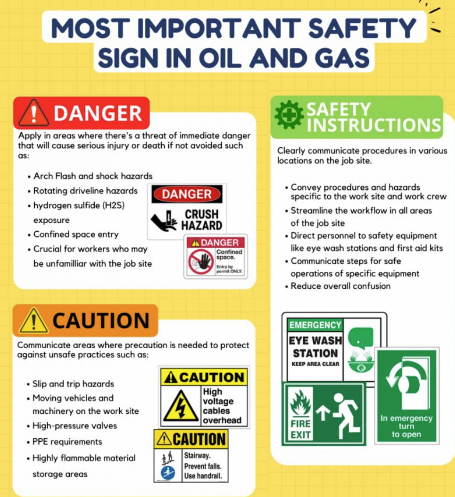

Safety in the Oil & Gas sector has come a long way from the rudimentary precautions of the past. While basic measures like Personal Protective Equipment (PPE) and emergency evacuation plans remain foundational, they are now part of a broader, more integrated safety system. Advanced protocols now encompass real-time monitoring, data analytics, and machine learning to provide comprehensive safety nets.

Real-World Case Study 1: Remote Monitoring Systems

A major oil company recently implemented a state-of-the-art remote monitoring system equipped with IoT sensors. These sensors constantly collect data on equipment status, worker health, and environmental conditions. The system can predict potential safety hazards and trigger alerts, enabling proactive measures before an incident occurs.

Beyond Regulatory Compliance

Regulatory standards offer a minimal safety threshold, but today’s environment demands more. Companies are taking a proactive approach to go beyond what’s required by law to protect their assets and workforce.

Real-World Case Study 2: Safety Culture Development

An upstream company launched a “safety-first” culture initiative aimed at encouraging employees to identify and report safety risks. Employees underwent extensive training on new safety protocols, and the company established a rewards program for reporting hazards. Within the first six months, reported incidents reduced by 15%, and the near-miss ratio improved significantly.

Technological Advances in Safety Measures

Cutting-edge technologies like AI, blockchain, and Big Data analytics are now being employed to create multi-faceted safety protocols. Artificial Intelligence is especially effective in predictive maintenance, identifying potential equipment failures before they happen.

Real-World Case Study 3: AI and Predictive Analytics

An offshore drilling company leveraged AI algorithms and predictive analytics to anticipate equipment malfunctions. By analyzing historical data and real-time inputs, the system could predict a malfunction several hours before it occurred, allowing for preventive action and reducing equipment downtime.

Conclusion

Safety in the Oil & Gas sector is not just a regulatory mandate; it’s a business imperative. Companies need to employ the latest technologies and develop a culture that goes beyond compliance to ensure the well-being of their workforce and assets. With the adoption of advanced safety protocols, firms can significantly minimize risks, thereby adding value to their business operations.